Oil mist lubrication

Oil-air lubrication is a proven technology for lubricating high-speed gears, highly dynamic guides or bearings with very small oil droplets. Especially at very high relative speeds, this minimal quantity lubrication is highly efficient, inexpensive and, in contrast to circulating oil lubrication, independent of position and acceleration.

Product overview

|

|

|

| |

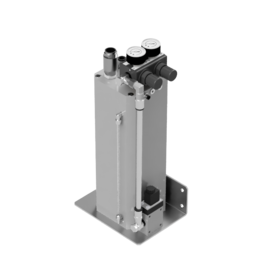

AB 350 Basic | AB 350 | AB 350 T | |

| Flow rate | 1 - 20 ml/hour | 1 - 20 ml/hour | 1 - 100 ml/hour |

| Aerosol-outlets | 1 outlet | up to 2 outlets | up to 14 outlets |

| Control | individual control of oil and air volume flow by an upstream control module | individual control of oil and air volume flow directly at the unit | individual control of oil and air volume flow by an upstream control module |

The devices for oil-mist lubrication are custom-made to customer specifications using our standard components of the proven Aerosol-Booster platform. The three designs shown have proved particularly successful in the past.

Operating principle

Conventional pump-based dosing systems often reach their limits, especially with very small quantities and many outlets. We therefore use the pumpless principle of our Aerosol Boosters to dose the smallest quantities of oil as an aerosol and transport it evenly over long distances to several outlets in the gearbox or bearing. Using nozzle inserts or small outlet holes in the gear or bearing to be lubricated, the aerosol is applied with pinpoint accuracy and accelerated so that it condenses and leads to the desired lubrication effect.

With our aerosol boosters, we can look back on over 25 years of experience in the field of pumpless tool lubrication. This technology for aerosol generation is used tens of thousands of times by our customers worldwide and convinces them every day with its reliability and maintenance-free operation.

Characteristics

- wear-free and reliable, no moving parts, pumps or electronics in the unit

- maintenance-free

- simplest operation

- lubricant dosing via adjustable differential pressure

- in combination with our tank extension: automatic refilling without interrupting ongoing operation with filtered lubricant from central reservoir

- platform design: individual adaptation to customer requirements

Further information

| Filling volume: | 2.8 liters |

| Unladen weight: | 10.0 - 11.0 kg |

| Control: | Switching on/off: pneumatic or electric (one solenoid valve) Operating parameters: two pressure regulators or individual control assembly |

| Compressed air supply: | 5 - 10 bar; dry and filtered |

| Aerosol outlet pressure: | 0.3 bar to maximum 85% of the inlet pressure |

- Control assembly consisting of pressure regulator pair and solenoid valve(s)

- Pressure monitoring

- Level monitoring

- Lockable pressure regulators

- Tank extension: automatic refilling from pressurized 10l central storage reservoir

- Ball valves for integration into the aerosol supply line

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com