Advantages

- central lubricant supply for several MQL devices

- wear-free and reliable: no moving parts, pumps or internal electronics

- MQL devices are refilled automatically and without interruption during operation

- Solenoid valves for integration into the refill lines of the MQL devices available as accessories

- reduced risk of contamination due to integrated lubricant filter

- Level monitoring with pre-warning in case of low level

Operating principle

The MQL devices are each connected to the tank extension with a standard hose line and a solenoid valve. The plant control unit monitors the fill levels of the MQL units and triggers a refilling process if required. For this purpose, the corresponding solenoid valve in the refill line is opened so that the lubricant, which is under excess pressure, is conveyed from the reservoir to the MQL unit. The refilling process does not affect ongoing operation. A tank extension can supply devices of different model families, as long as the same lubricant is used.

Further information

Technical specifications

| Filling volume: | 10 liters |

| Unladen weight: | 10 kg |

| Compressed air supply: | 2 - 10 bar; dry and filtered |

| Zertifizierung: | CE 0036, approved for 10 bar |

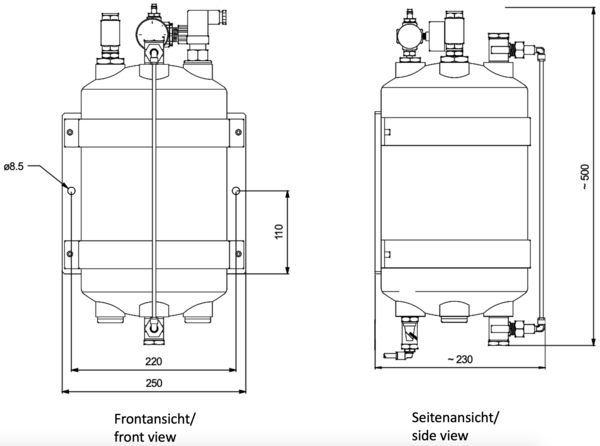

Dimensions

A free space of 300 mm is required above the tank for unobstructed filling. All dimensions in mm.

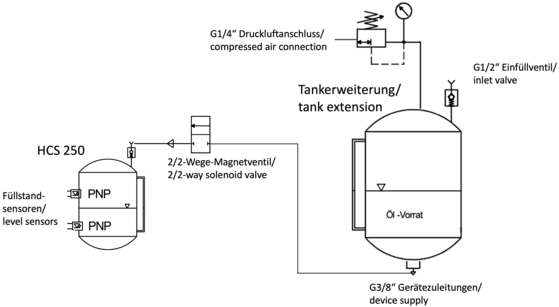

Application example 1

Tank extension for automatic filling of a HCS 250:

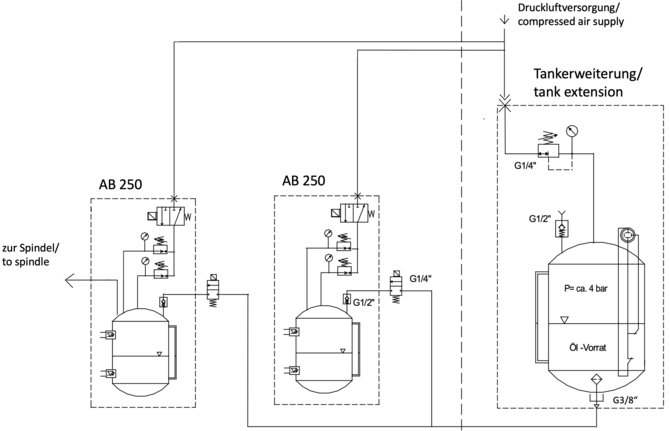

Application example 2

Tank extension for automatic filling of a HCS 250:

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com