Special designs: Oiling, greasing and preservation

In individual projects, we develop customized solutions for your lubrication, greasing or preservation task. In doing so, we can often rely on our standard components for dosing, conveying and application of liquid media. Our solutions are used worldwide by renowned customers in manual assembly systems, collaborative robot cells or fully automated systems.

Spectrum

We supply both manually operated units for manual workstations and turnkey solutions for installation in semi- or fully-automated systems:

- Oiling or greasing of O-rings, components and bearing points

- Semi-automatic application of oil/grease as assembly aid

- Rust protection and preservation of intermediate products or stock items

- Corrosion protection of weld seams

- Application of protective and release agents during welding and laser cutting

- Spray mist extraction with integrated air-liquid separation

Application Examples

The solutions presented here represent only a small selection of our range of capabilities. Please feel free to contact us at +49 (0)721 9575038 or support@tkm-systems.com for an individual consultation.

Oiling

Greasing

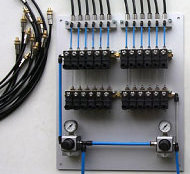

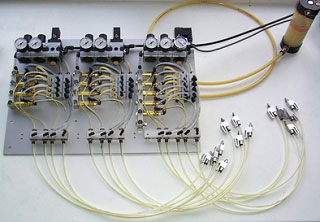

Greasing system for small gearboxes, integrated into an automated assembly line:

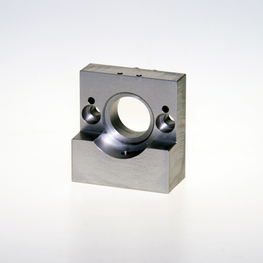

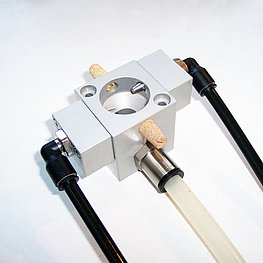

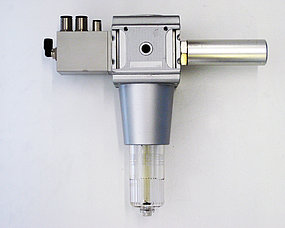

Greasing device for aluminum external threads:

Single-hand/robotic operation: The spraying process is triggered automatically when a part is inserted. The flow rate of the grease can be adjusted by a throttle valve. The grease reservoir is filled from cartridges using a grease gun. The device can either be operated manually, or integrated into a robot cell.

Typical fields of application:

- Greasing of components and bearing points in automated systems, often component handling with robots

- Semi-automatic application of grease in manual assembly

- Greasing of bearings or gears as lifetime lubrication

Preserving

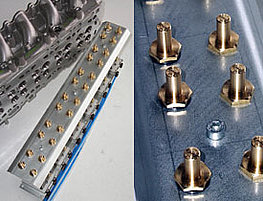

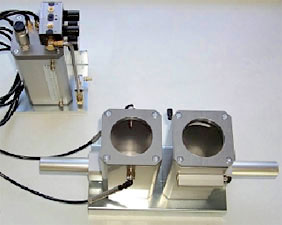

Combination of ① blow-off/suction unit for parts cleaning (e.g. of dust and emulsion residues) and ② preservation unit for subsequent preservation with oil. Suitable for parts up to 80mm outer diameter:

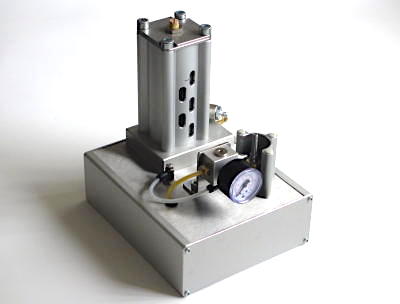

Device for surface preservation of cylindrical components up to 20mm outer diameter with integrated suction:

Typical fields of application:

The preservation of components can serve, for example, to protect against rust or corrosion or to sterilize them.

- Preservation of cavities, packaging or components.

- Preservation of semi-finished products, intermediate products or products before storage

- Corrosion protection, rust protection of surfaces

- Device for preserving a weld seam (e.g. circumferential seam on pipe)

Miscellaneous

Extraction device with air-liquid separation. In combination with additional blowing air, it can be used for effective component cleaning (e.g. from emulsion):

Test setup for lubricant tests:

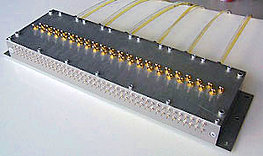

Spring-loaded tank with 32ml filling volume. Guarantees a position-independent and bubble-free delivery of liquids:

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com