Minimum quantity lubrication with external feed

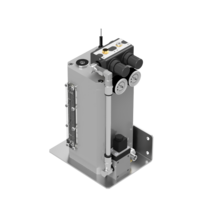

With the HCS 250 and the HV 250, we offer plug-and-play devices for the ideal lubrication of your tools with liquid lubricants. For the use of paste-like lubricants and greases, we offer the PSD 250, a unit that is easy to operate and install.

All dosing processes require no moving parts, no complex dosing equipment and no internal electronics. Therefore, our units are characterized by highest reliability and the best possible economic efficiency at the same time.

Product overview

Characteristics

- Dosing of lubricant and additional spray air independently adjustable

- Nozzles can be switched on/off independently with solenoid valves

- Inexpensive and compact nozzles available for a wide range of applications

- Spraying distance from 10 mm to 300 mm, depending on the nozzle (spray jet opening angle of either 5° or 10°)

- Homogeneous spray jet with relatively large liquid particles due to vacuum atomization at the nozzle outlet

In combination with the fast-flowing air-jacket jet, mist is thus successfully avoided

- Electrical, pneumatic or manual control possible

- Compact coaxial hose for lubricant (inner hose) and spray air (jacket hose) protects the inner hose from damage

- Precisely adjustable and uniform delivery of lubricant from an pressurized reservoir

- Extensive range of accessories including sensors, nozzles and spraying devices available

- Automatic filling of several MQL units with liquid lubricants from a central reservoir possible

Application areas

In addition to turning and milling, successful applications include:

- Drilling

- Sawing

- Tapping/ forming

- Machining of composite & sandwitch materials

- Flow forming

- Reaming

- Nibbling and punching

- Deep drawing

- Broaching

- Cold forming

In addition, our devices are optimally suited for component preservation:

- Interior conservation of hollow bodies

- Preservation of weld seams (temporary rust protection)

- Corrosion protection of (electric) motor shafts

Environmental protection

Less lubricant consumption and the avoidance of disposal waste (only dry chips need to be disposed) cause a substantially improved protection of working conditions and the environment. This is - today more than ever - an important factor in manufacturing, as active environmental protection matters to all of us.

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com