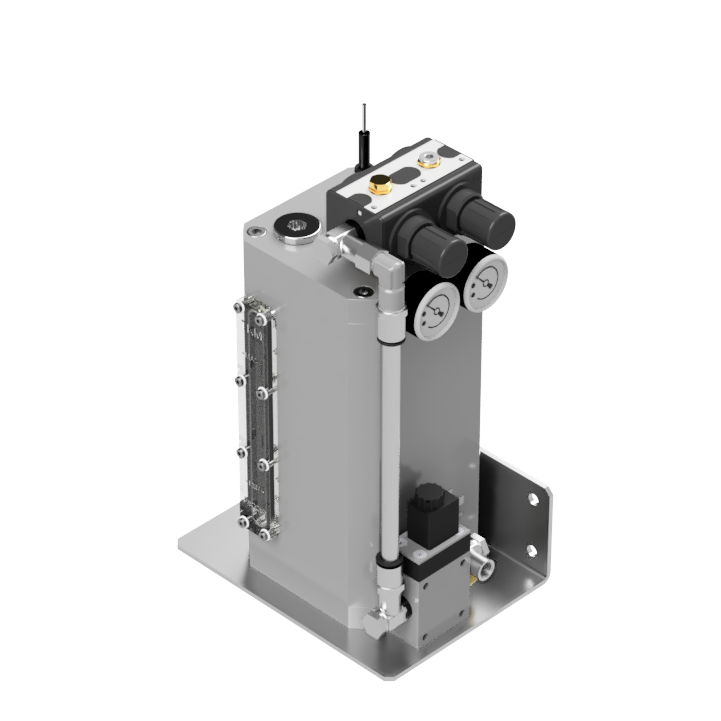

PSD 250

Minimal lubrication system for external supply of flowable pastes and greases

- especially suitable for free-flowing pastes and greases with a viscosity of approx. 1000 mm²/sec and above

- flexible bottom disk prevents sedimentation and thus deposits of solid particles of the lubricant

- simultaneous operation of up to 6 nozzles

- de-/activation of individual nozzles/outlets with optional valves

Operating principle

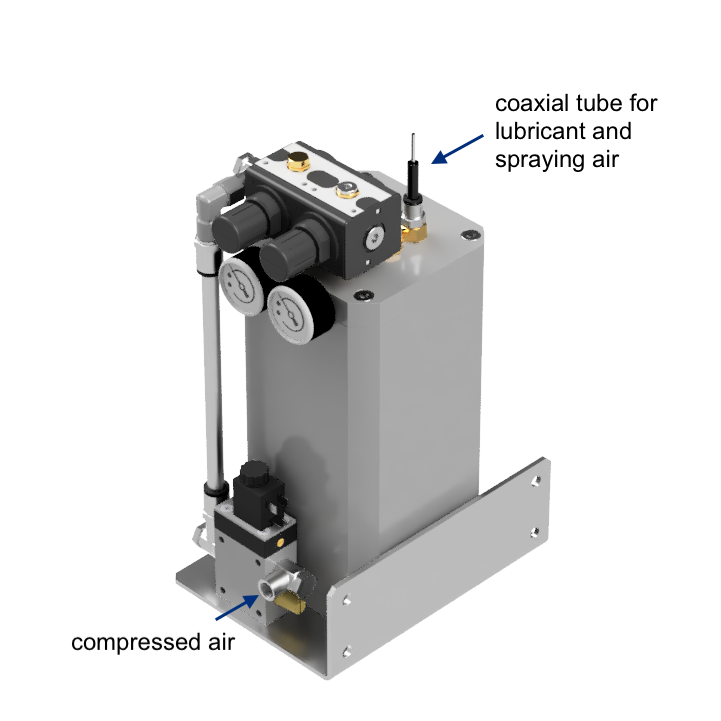

The PSD 250 minimum lubrication system meters highly viscous, free-flowing pastes or greases with viscosities from approx. 1000 mm²/sec. The volume flow can be reproducibly adjusted via the delivery pressure, which is set with a pressure regulator. The maximum possible flow rate depends on the viscosity of the lubricant and the length of the supply line to the nozzle. A second pressure regulator is used to meter the spray air independently of this. Both media are conveyed separately to the nozzles in coaxial lines.

A flexible base plate prevents sedimentation of solid lubricant particles, so that lubricant deposits in the unit are permanently avoided.

The dosing process does not require any moving parts, complex metering equipment or internal electronics. Throttle valves, which are prone to clogging due to their principle, are not used. Therefore, the PSD 250 is characterized by highest reliability and at the same time best possible cost-effectiveness.

Characteristics

- two pressure regulators for independent metering of lubricant and spray air

- electrical or manual control of the spray function with only one switching signal

- independent activation/deactivation of individual nozzles with optional solenoid valves

- pressurized reservoir for lubricant delivery without pump or other moving parts

- flexible base plate prevents sedimentation of solid lubricant particles

- reproducible flow rates even at low lubricant dosages

- extremely fast response even with long supply lines to the nozzle

- suitable nozzles and spraying devices available for various applications

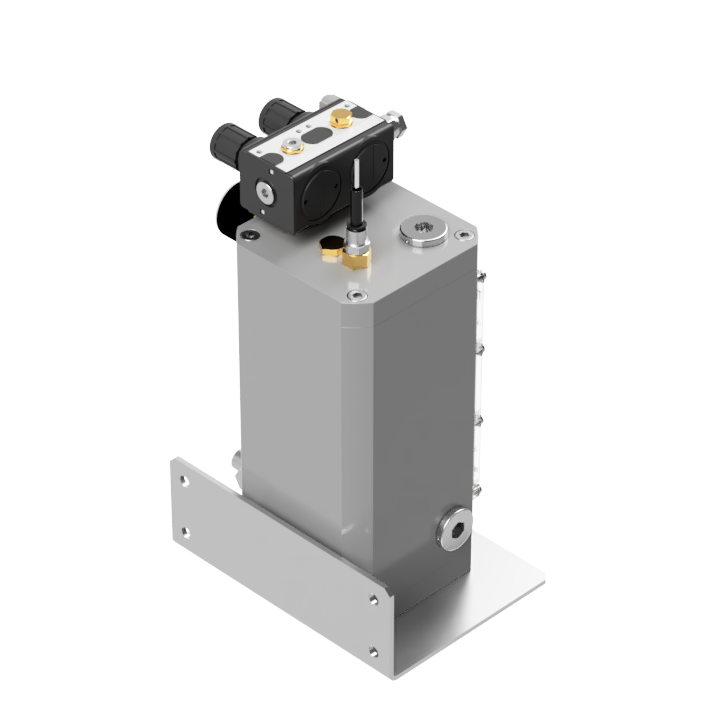

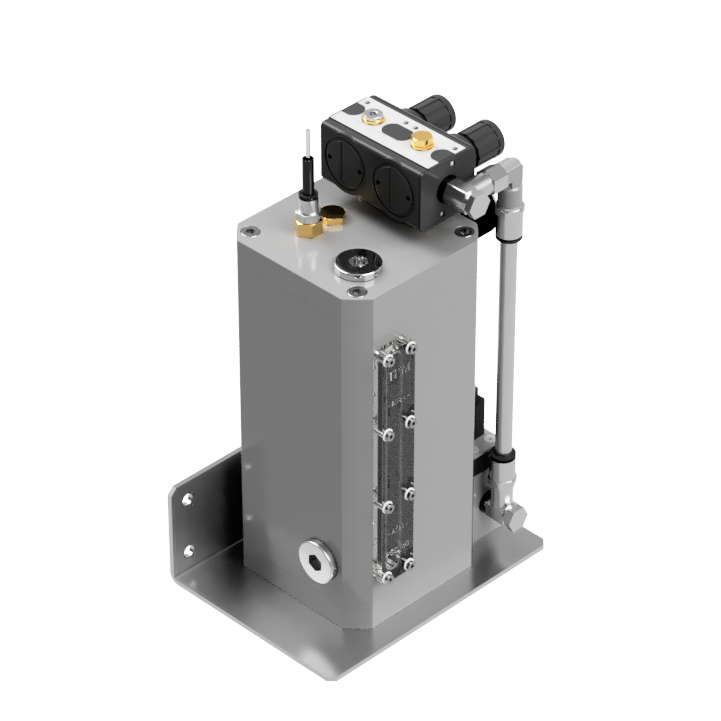

Versions

The PSD 250 is offered with up to six outputs.

The spray function is de-/activated via an electrically, mechanically or pneumatically actuated valve for all outputs together. Individual outputs can be de-/activated via optional coaxial solenoid valves.

Components

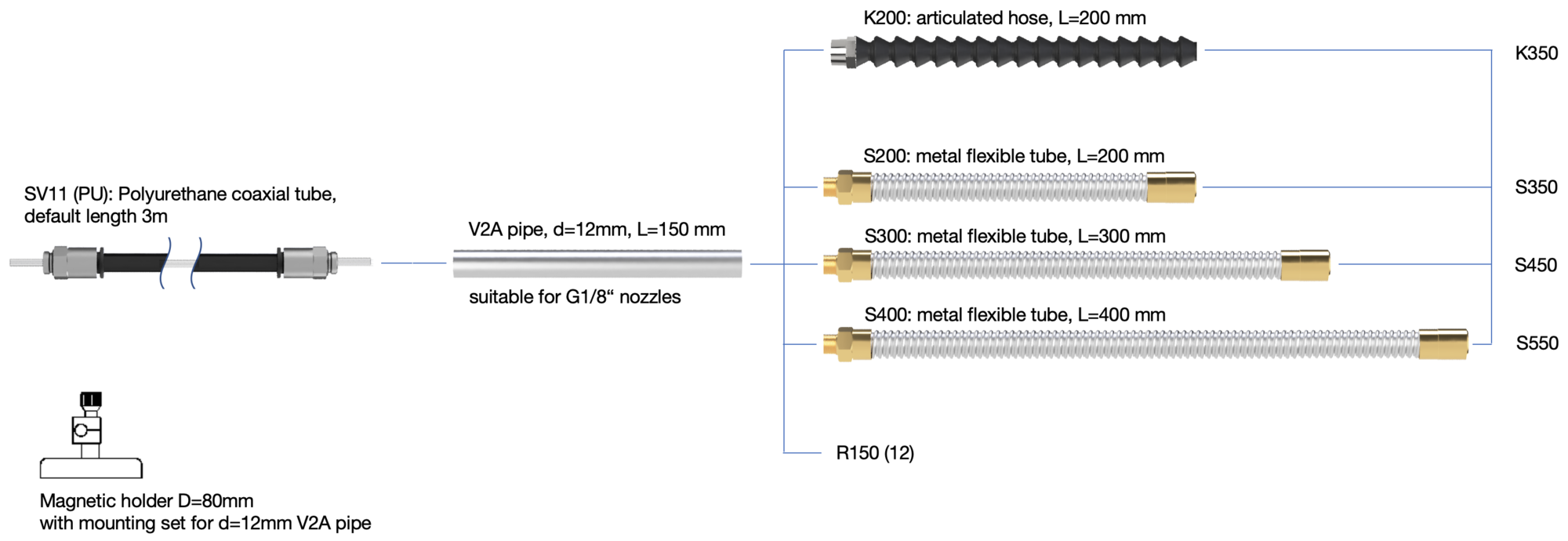

Spraying devices

Our spraying devices are the link between the dosing unit for external feeding (HCS, HV or PSD) and the application-specific nozzles. They are used to transport the media and to fix the nozzle in the work chamber of the machine.

The precisely metered lubricant is transported in the inner hose of the coaxial hose, protected from the outer hose - in which the spray air is conveyed. The standard polyurethane coaxial hose can optionally be replaced by a metal braided coaxial hose.

The coaxial hose is typically connected to a V2A mounting tube, which is used for installation in the working area of the machine. As an optional accessory, we offer a holding magnet with a suitable mounting set for this purpose.

For precise and changeable alignment, our nozzles with G1/8" connection can be screwed to a flexible articulated or metal hose.

The length specifications of the coaxial hose, the V2A tube and the articulated hose are to be understood as standard values. We will be pleased to supply you with application-specific designs.

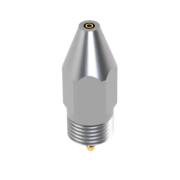

Nozzles

Our nozzles operate based on the coaxial principle, in which the lubricant spray jet is stabilized by a surrounding air jacket jet. A low-pressure atomization occurs at the nozzle outlet, which ensures a homogeneous spray jet with relatively large liquid particles. The lubricant jet, which is protected by the air jacket jet, can be sprayed specifically onto the tool over relatively long distances.

Nozzle assortment

PSD 10/10

| PSD 05/10

|

Spray cone: 10° Connection thread: G1/8" Spraying distance: up to 80 mm | Spray cone: 5° Connection thread: G1/8" Spraying distance: up to 150 mm |

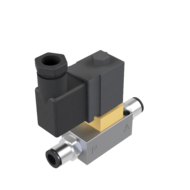

Coaxial solenoid valves

Our MQL devices for external feeding can be equipped with up to six outputs, depending on the design. The media feed is (de)activated for all outputs together with a switching signal on the device. In order to nevertheless be able to control individual outputs/nozzles separately, we offer coaxial solenoid valves for integration into the nozzle feed lines.

2/2-way valve for integration into a coaxial line: Allows the lubricant to be switched off individually, |  |

2x 2/2-way valve for integration into a coaxial line: Allows the lubricant and the spraying air to be switched off individually |  |

Sensors

We offer the following sensors as standard for monitoring the PSD 250:

Pressure monitoring: Electronic pressure switches from various manufacturers |  |

Level monitoring: point level sensors for flowable pastes and greases |  |

Further information

A free space of 300 mm is required above the unit for unobstructed filling. All dimensions in mm.

| Filling volume: | 1.8 liters |

| Unladen weight: | 8.0 kg |

| Control: | A switching signal for de-/activation of the lubrication function:

|

| Compressed air supply: | 4 - 6 bar; dry and filtered |

| Operating pressure: | 1 - 6 bar (delivery pressure) |

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com