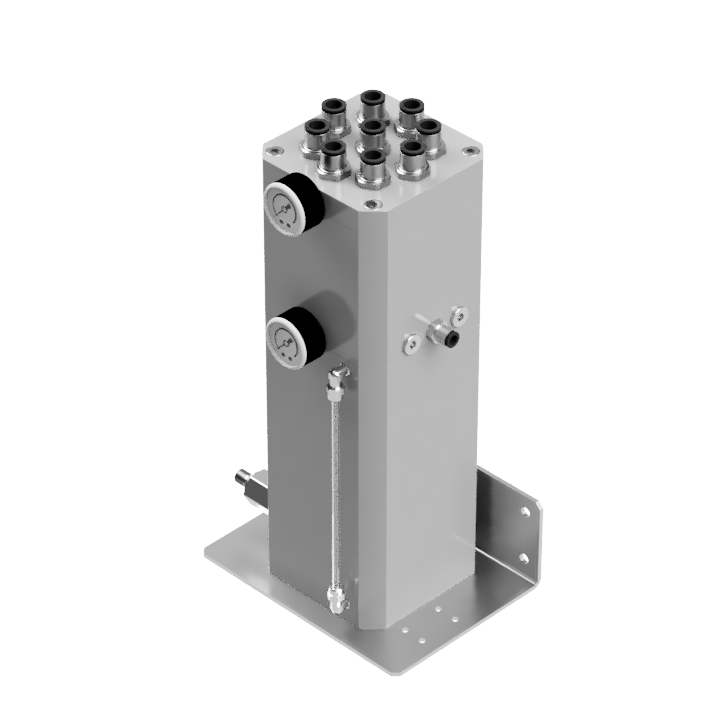

Operating principle

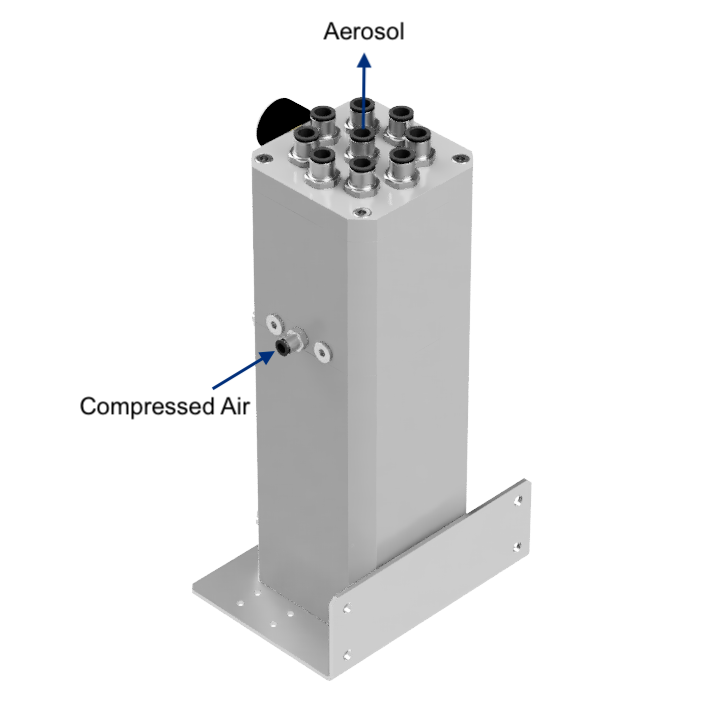

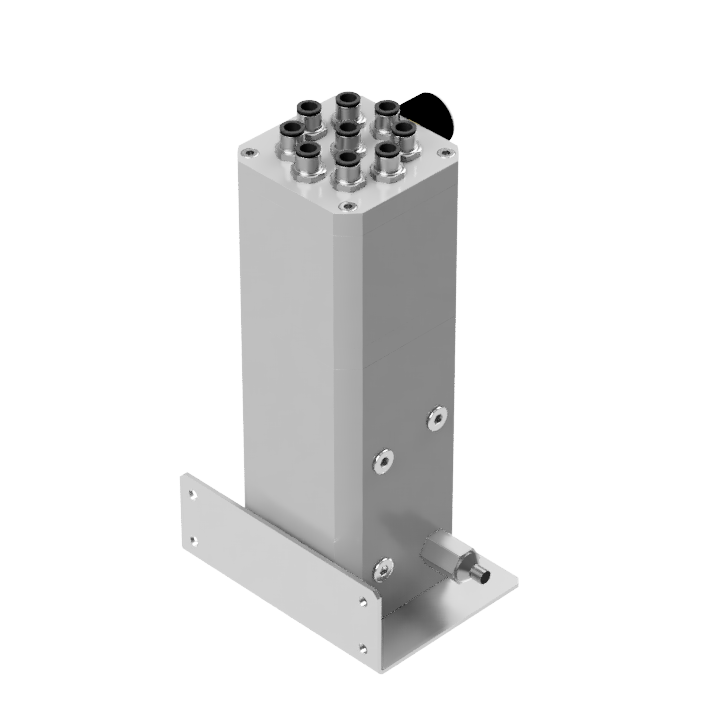

The Aerosol Booster generates an air-liquid mixture with extremely small liquid particles from non-water-miscible lubricants. This aerosol is suitable to be conducted over longer distances in hoses as well as through rotating spindles and tools. The cooling channels of the tools cause a nozzle effect through which the incoming aerosol condenses, i.e. oil and air are separated. This results in precise oil lubrication at the tool.

The integrated aerosol distributor can supply up to 16 tools/spindles simultaneously. Individual aerosol supply lines can be temporarily switched off by additional ball valves.

Advantages

- wear-free and reliable, no moving parts or electronics in the unit

- especially suitable for multi-spindle drilling heads

- compact design despite the large oil flow rates

- suitable for all tool sizes

- individual outputs can be switched on/off by ball valves

- in combination with our tank extension: automatic refilling during operation with filtered lubricant from central reservoir

Further information

Versions

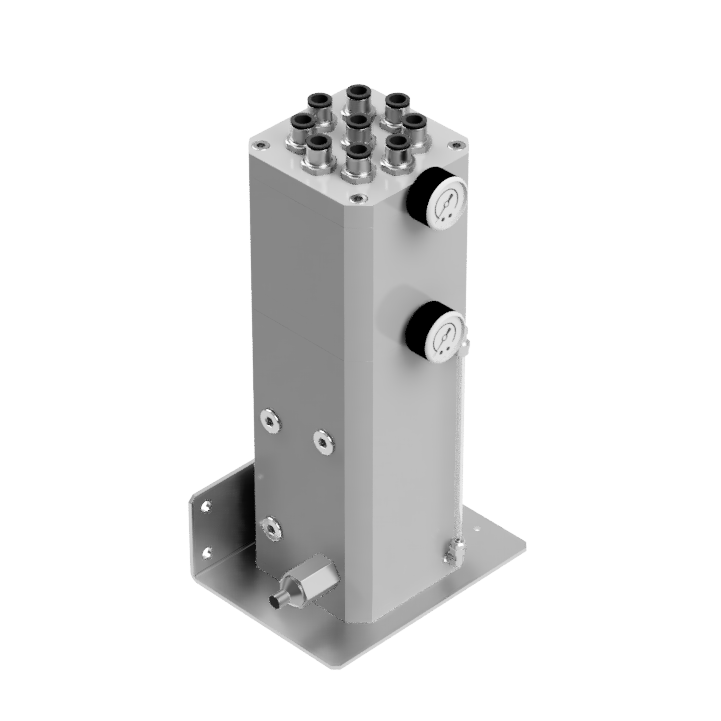

The aerosol booster AB 250 Special T is manufactured application-specific. The variants differ in the maximum oil flow rate, the operating pressure, the number of outputs and the type of control:

| Delivery rate: | as required, max. 250 ml/hour |

| Operating pressure: | up to 6 or up to 10 bar |

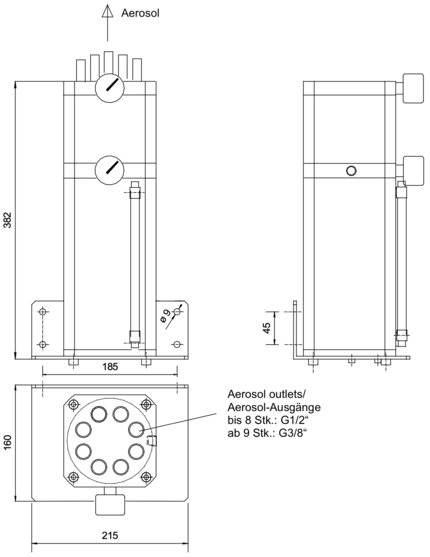

| Aerosol outlets: | max. 16 pcs. (individually switchable with additional ball valves) |

| Control: | individual according to customer requirements, see Control options |

Delivery specifications can be taken into account when selecting pressure regulators and solenoid valves.

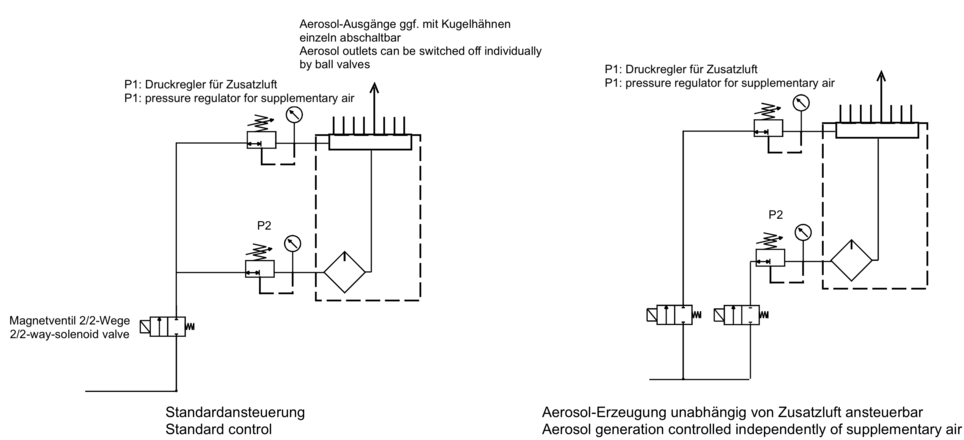

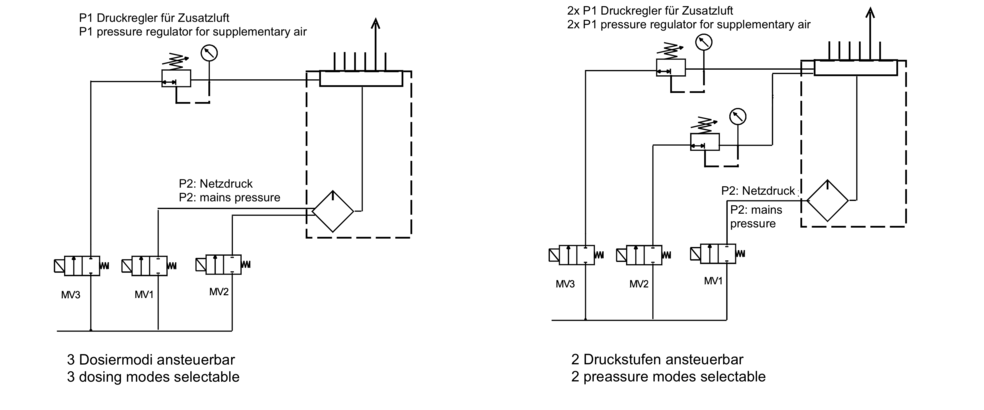

Control options

The control of the AB 250 Special T is realized customer-specific. Four variants are listed below as examples:

Example 1 and 2

Example 3 and 4

Dimensions

All dimensions in mm.

Technical specifications

| Filling volume: | 1.8 liters |

| Unladen weight: | 10.0 - 11.0 kg |

| Control: | - Switching on/off: Solenoid valve (one M function), |

| Total volume flow: | DN 10 |

| Compressed air supply: | 5 - 10 bar; dry and filtered |

| Aerosol outlet pressure: | 0.3 bar up to maximum 85% of the inlet pressure |

Accessories

- Individual control assemblies consisting of pressure regulator pair and solenoid valve(s)

- Pressure monitoring

- Level monitoring

- Tank extension: automatic refilling from pressurized 10l central storage reservoir

- Lockable pressure regulators

- Nozzles for external feeding of the aerosol

- Ball valves for integration into the aerosol supply line

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com