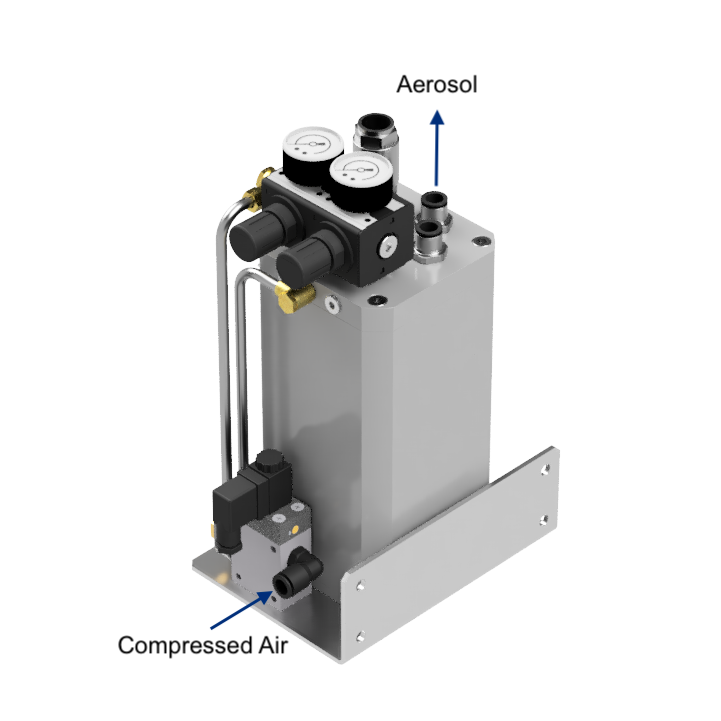

Aerosol-Booster AB 250 Standard

Minimum lubrication system for internal feed with automatic dosage adjustment

for machining centers and special machines with one to six spindles

TKM Self-Regulation: independent adaptation of lubrication to medium to large tools

- only one control signal required for operation

Operating principle

The Aerosol Booster generates an air-liquid mixture with extremely small liquid particles from non-water-miscible lubricants. This aerosol is suitable to be conducted over longer distances in hoses as well as through rotating spindles and tools. The cooling channels of the tools cause a nozzle effect through which the incoming aerosol condenses, i.e. oil and air are separated. This results in precise oil lubrication at the tool.

The lubricant consumption depends on the air volume flow and thus on the operating pressure and the outlet cross-sections of the tools and is automatically adjusted by the TKM Self-Regulation in the unit.

Advantages

- wear-free and reliable, no moving parts or electronics in the unit

- no more need to control tool-dependent operating modes, operating errors are avoided

- suitable for a wide range of medium to large tools from approx. 0.8 mm cooling channel diameter upwards

(extended tool spectrum: AB 250 Automatic) - plug-and-play: only one M-function required for control

- in combination with our tank extension: automatic refilling (of several MQL units) during operation with filtered lubricant from central reservoir

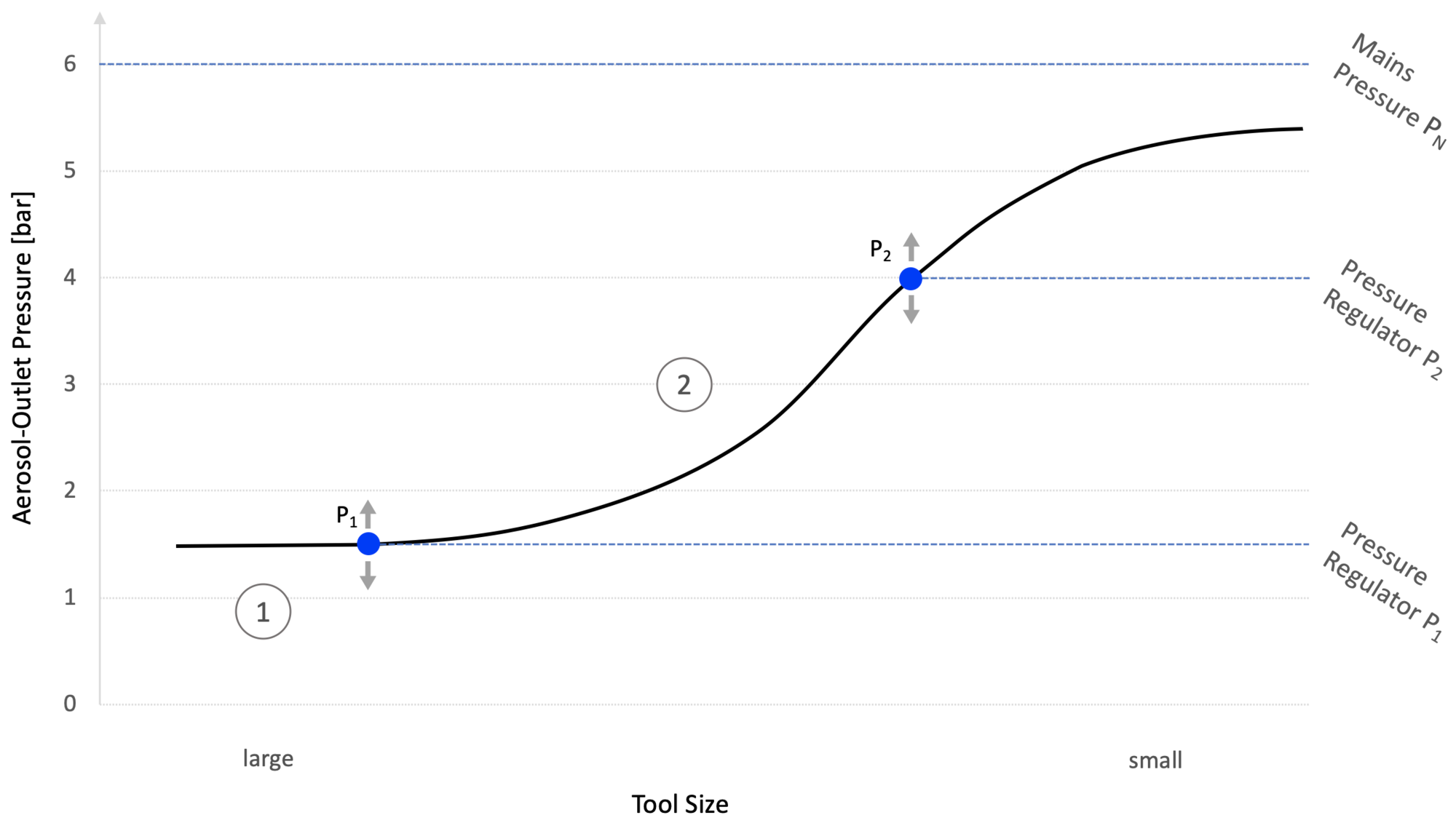

TKM Self-Regulation

The required lubricant quantity, which depends on the cutting process and tool, does not have to be controlled manually on the AB 250 Automatic. Instead, the lubricant dosage is controlled automatically thanks to the TKM Self-Regulation system, which has proven itself for more than 20 years and is in use thousands of times over.

The aerosol quantity provided at the tool and the oil-air ratio results from a superimposition of several different aerosol generators in the unit. During the running process, individual aerosol generators continuously deactivate/activate themselves and automatically regulate their output as required on the basis of an (adjustable) dosing characteristic curve (see graphic below). A purely pneumatic regulating system is installed for this purpose. The measured variable is the tool- and process-dependent aerosol dynamic pressure, which adjusts itself in particular as a function of the current lubrication conditions (too much/too little) and the cooling channel diameter (small/large). The control system operates continuously.

For simplified illustration, two cases will be considered here as examples:

In the case of a tool with large cooling channels (x-axis, left), a low aerosol dynamic pressure occurs at the tool. The aerosol generators work according to the characteristic curve in the operating case ① with a large differential pressure (between mains pressure PN and dynamic pressure) and consequently supply an increased aerosol quantity suitable for the tool.

The operating case ② (x-axis, center) occurs, for example, with a tool with a medium cooling channel diameter (e.g. 1 mm). In principle, smaller cooling channels cause a reduction in the aerosol volume flow. In order to still achieve sufficient lubrication, the aerosol pressure and the oil content in the aerosol are automatically increased overproportionally in accordance with the dosing characteristic, so that the lower volume flow is compensated.

In 1995, the first aerosol boosters were produced with the AB250 LC. It has 3 aerosol generators of different sizes which can be activated individually or in groups. In many applications and extensive tests, the optimum setting for each case was determined and documented together with our customers for a wide range of tools. These results formed the basis and the benchmark for the characteristic control curve of the AB250 Standard and AB250 Automatic. In a figurative sense it was the replacement of a manual gearbox by an automatic gearbox which automatically shifts into the most suitable gear.

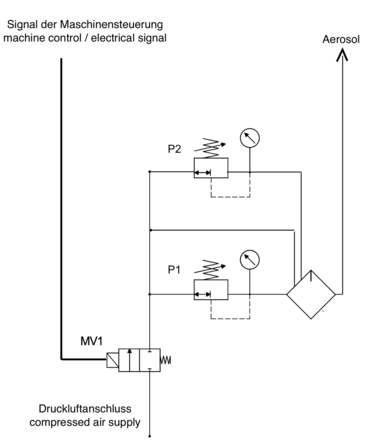

During initial commissioning of your new AB 250, the standard characteristic curve can be fine-tuned for your individual process, if necessary, by means of the two pressure regulators P1 and P2 and the two switching points of the hysteresis pressure switch SP1 and SP2. The result: the appropriate lubricant dosage is automatically set for each tool used - without the need for external control or internal electronics. To control the devices with TKM self-regulation, all that is needed after commissioning is a switching signal to switch the lubrication on/off.

Further information

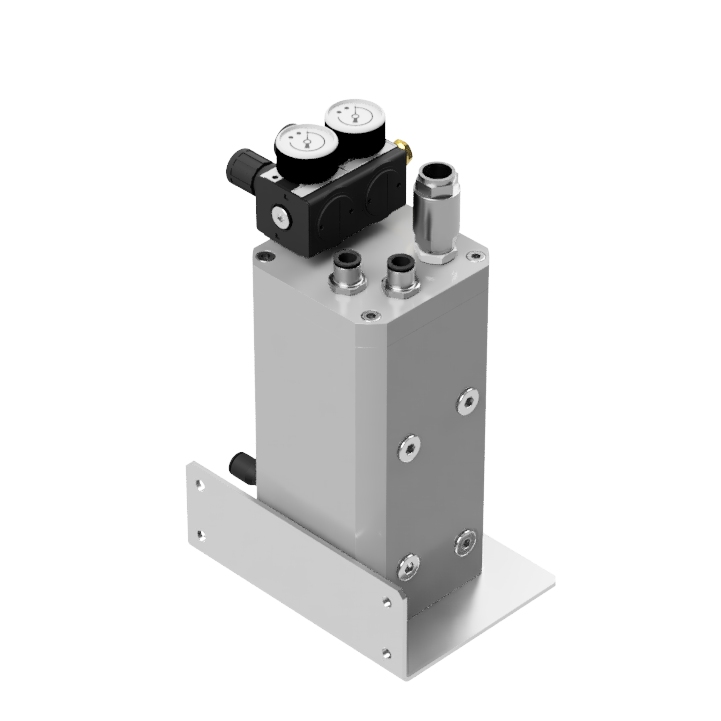

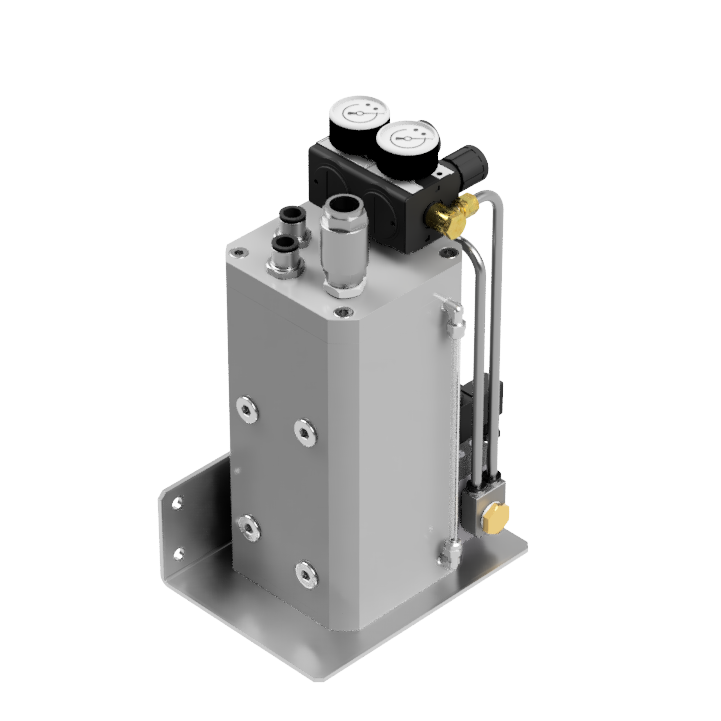

Versions

The Aerosol Booster AB 250 Standard is offered in the following versions:

| Delivery rate: | up to 32, 75 or 110 ml/h |

| Operating pressure: | up to 6 or up to 10 bar |

| Aerosol outlets: | 1, 2, 4, 6 (individually switchable with additional ball valves) |

Dimensions

A free space of 300 mm is required above the unit for unobstructed filling. All dimensions in mm.

Connection diagram

Technical specifications

| Filling volume: | 1.8 liters |

| Unladen weight: | 8.0 - 9.0 kg |

| Control: | switching on/off: Solenoid valve (one M function) |

| Total volume flow: | DN 9 |

| Compressed air supply: | 5 - 10 bar; dry and filtered |

| Aerosol outlet pressure: | 0.3 bar to maximum 85% of the inlet pressure |

Accessories

- Pressure monitoring

- Level monitoring

- Lockable pressure regulators

- Tank extension: automatic refilling from pressurized 10l central storage reservoir

- Nozzles for external feeding of the aerosol

- Ball valves for integration into the aerosol supply line

Please do not hesitate to contact us:

Technical support: +49 (0)721 573789 or support@tkm-systems.com

Quotation requests: info@tkm-systems.com